Xiamen, Fujian Nov 15, 2025 (Issuewire.com) - Global manufacturing is constantly changing, driven by new technologies and market changes. Understanding these seismic shifts are essential for any Professional Heavy Machining Manufacturer who wants to lead, rather than following. The FMA 2026 Annual Meeting, a premier event organized by the Fabricators & Manufacturers Association, was centered around this forward-looking perspective. The meeting, which took place from February 24th through 26th in Clearwater Beach, Florida brought together industry leaders to discuss the most important trends for the next few years. FMA 2026's insights, from advanced automation to supply-chain resilience, are not only relevant for the U.S. but are also shaping the future of heavy-machining in China and elsewhere.

FMA 2026: Navigating The Future of Manufacturing

The FMA Annual meeting is a vital compass to the metal fabrication industry. It provides a forum where business leaders can share strategies and examine emerging technologies. The event in 2026 focused on how businesses can thrive amid a backdrop rapid change. It placed emphasis on business leadership, technological innovation, and market insight. The main takeaway was that the future belongs to people who embrace change, and not those who resist.

The New Technological Imperative

What are the new technologies that will define the next generation in manufacturing? According to FMA experts the answer is a powerful mix of smart automation, digital integration, and digitalization.

Smart Automation with AI Integration

The age of simple robots that are programmed is over. FMA 2026 emphasized the rise of intelligent automaton and the use of artificial intelligence in manufacturing. AI-driven systems are now able to optimize machine tool paths and predict maintenance requirements in order to minimize downtime. They can also perform real-time checks of quality with an accuracy that exceeds human capabilities. This technology can make a huge difference in heavy machinery where even a fractional millimeter of error can mean the difference between failure and success. The focus of the discussion was on how smart systems can boost worker productivity and ensure their safety by automating repetitive, physically-demanding tasks.

Digital Twins & Simulation: A Virtual Blueprint

More On 360mediahub ::

- Albanian Artist Naldi Reaches 5 Billion TikTok Views and 150 Million YouTube Streams

- Imagen Network Fuses AI and Decentralization to Empower Creator Economies

- HGHsells.com Unveils New Online Platform Dedicated to Longevity, Wellness, and Peak Performance in the United States

- NEW interviews from Maelstrom’s Chief - Arthur Hayes. Access the latest insights on the markets, digital assets and Web3

- How a Retired Nurse Earned a Porsche from Home Using Moon Hash and Cryptocurrency

Digital twin technology was another major trend that was explored. Manufacturers can create a virtual replica before touching a single raw material of a component or factory floor. This allows them to simulate production processes and test design changes in a virtual environment. This innovation reduces the cost of prototyping and time to market. This is the best way to make sure a design works before you commit to expensive production runs. This technology is especially valuable for large and complex projects, where mistakes can be costly. It has a profound impact on how companies design and engineer.

Sustainability and Supply Chains

FMA 2026 addressed macro-economic factors that impact the industry. The conversation focused on two key areas: supply chain strategy and sustainability.

Resilient and localized supply chains

Recent global disruptions exposed the vulnerability of an overly centralized supply chain. The summit focused on the need for more resilient, localized, and distributed manufacturing networks. Professional Hard Machining Manufacturer is not excluded, but they must prove their speed, reliability and advanced capabilities to be a trusted partner in these new, diverse networks. In the future, it's about collaboration and not competition. The focus is on creating robust partnerships that are able to withstand unexpected challenges.

The Push for Greener Manufacturing

How can industry create big things without a large footprint? FMA 2026 panelists discussed the increasing demand for sustainable manufacturing. The panels discussed the growing demand for sustainable manufacturing practices. The move to more energy-efficient machinery and greener manufacturing methods for heavy fabrication is not only an ethical decision, but also a business imperative. It opens up new markets and environmentally-conscious clients.

Openex - A Case Study on Modern Heavy Machining

The FMA Annual Meeting laid out the road map, but companies like Openex have already begun to build the future. Openex, a leading manufacturer in fabricated metal products and steel weld components, embodies all the principles discussed at this summit. They have proven themselves to be a leader of Heavy Machine with their extensive experience and modern equipment.

Core advantages: Quality, expertise, and innovation

Openex's leadership in the market is not a result of chance. It is a direct result from committing to innovation, quality and service. They are living examples of how to seamlessly integrate the latest technology trends with decades worth of practical experience.

At leastfew companies provide the services like Openx doeswhich include

Self-developed automated welding system

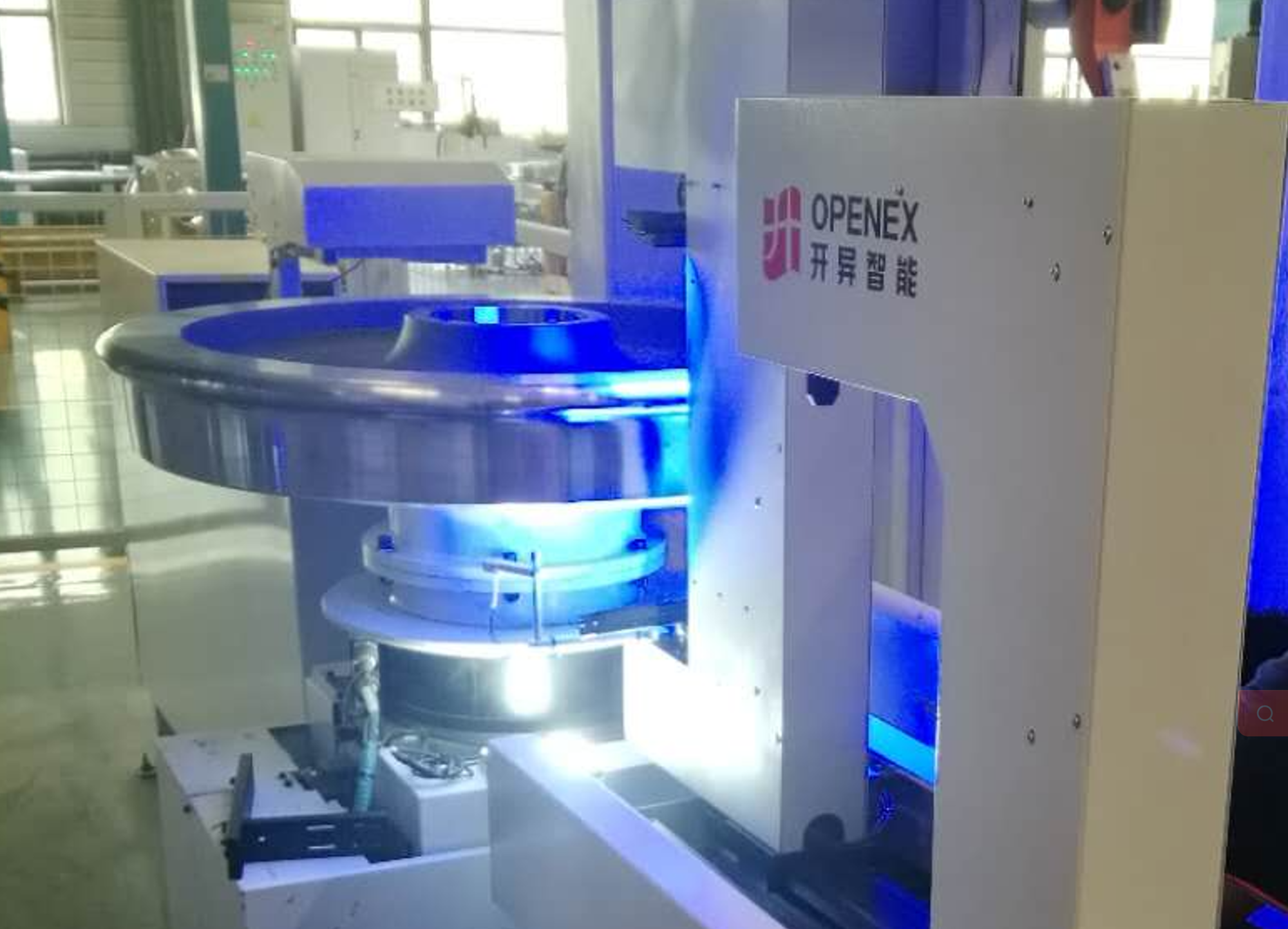

Self-developed AI vision inspection system

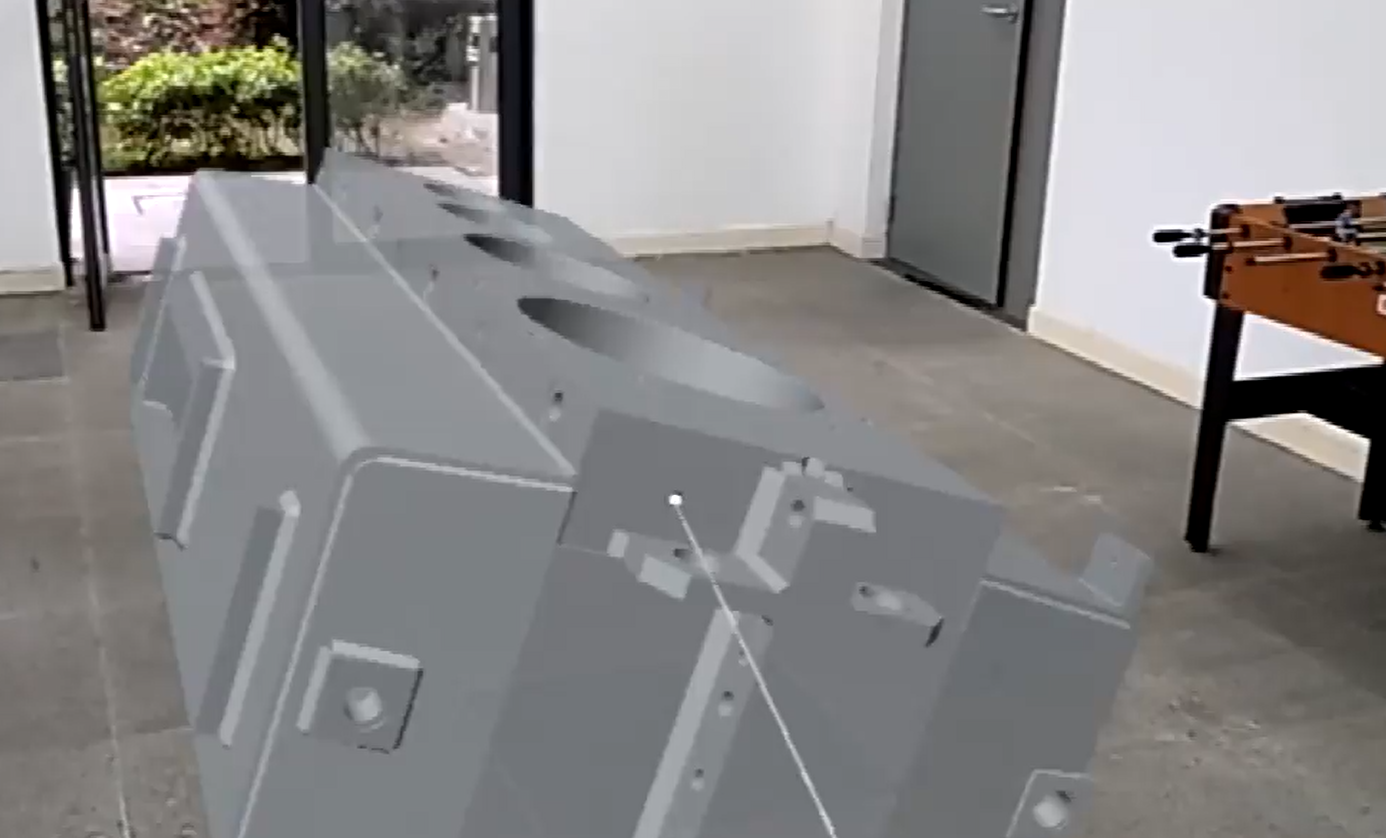

Self-developed AR remote collaboration system

Modern Equipment is More Than Machines

Openex's core capabilities are a fleet advanced equipment reflecting the FMA 2026 trends. It's not just about large machines, but using CNC machinery with sophisticated control to achieve micron level precision on massive components. The investment they make in automated welding, digital measurement tools and advanced surface-treatment technology ensures every fabricated product is up to international standards. They can produce large quantities of high-quality production as well as complex prototypes.

The Power of Experience and Service

Openex's real strength is its team, not just the technology. Their engineers and artisans bring a wealth of experience to each project. Openex can manage the entire project, from initial consultations to final production. Openex is more than just a designer; they are a partner who offers insights on how to increase efficiency, lower costs and make sure the final product matches the exact specifications of the client. Their business philosophy is based on providing customers with the best quality and service.

From prototypes to industry-critical components

Openex is not limited to one sector. They are a preferred manufacturer in many industries because of their ability to provide high-quality solutions that are customized. They are not a one size fits all solution. Each product is a testimony to their engineering expertise and versatility.

Openex produces robust, custom-fabricated parts for the mining and engineering sectors. These components are designed to withstand harsh conditions, from drill rig frames to hoist systems, to structural supports that support excavation equipment. Openex's expertise in the oil-and-gas industry is used to manufacture complex high-pressure equipment, such as valve bodies, pipe-manifolds and large-scale structures for onshore and offshore use.

Openex is the only company that can deliver the high precision required by the automotive industry and aerospace. Openex produces everything from engine mounts and heavy-duty chassis for large vehicles, to complex precision-machined moulds for aerospace fixtures and tooling. Openex is a key supplier of components to the Energy industry. These include large turbine shafts and generator housings as well as foundational steel structures. Openex also provides sructural steel beams for large buildings and bridges, as well as fabricated components. This ensures the safety and integrity critical infrastructure.

Openex - The Global Partner of a New Era

Openex is a China heavy machining manufacturer that stands out in a world where efficiency and reliability are increasingly important. They have successfully incorporated the trends discussed at FMA 2026 into their everyday operations. This is a model for modern manufacturing which combines high-quality with cost-effectiveness.

Openex's One Stop Heavy Machining Services removes the complexity of large-scale projects and allows clients to rely on a single partner for prototype to production. The company's comprehensive approach is built on the foundation of service, quality and technical expertise. This makes them a trusted brand in the industry. Openex, a leader in heavy fabrication and machining, is not only prepared, but also at the forefront of this revolution. It helps its clients create the world of tomorrow.

To learn more about their capabilities and how they can elevate your next project, visit their website: https://www.cncmetalworking.com/

Media Contact

Openex

+86 186 5928 0806

Our Offices:No. 99 Yilan Rd., Xiamen , CN.

Source :Openex

This article was originally published by IssueWire. Read the original article here.

6 day's ago