Xiamen, Fujian Nov 15, 2025 (Issuewire.com) - The industrial sector is the backbone of the global economy, and at its core lies the critical work of welding and fabrication. This is where raw materials are transformed into the essential components that power everything from mining operations to aerospace exploration. As project complexity and quality standards rise, the industry has shifted from a fragmented collection of specialized vendors to a network of comprehensive, single-source providers. A truly Professional Welding And Fabrication Supplier today must offer more than just a servicethey must provide an end-to-end solution.

The Evolving Landscape of Welding & Fabrication

Industrial welding and fabrication have always been about joining materials to create something bigger, stronger, and more functional. However, the methods and expectations of this field have undergone a revolutionary change. What was once considered a traditional trade is now a highly technical discipline driven by precision engineering, advanced metallurgy, and digital integration. The market demands components that are not only robust but also perfectly consistent, traceable, and built to the highest safety standards. This shift is reshaping how manufacturers operate, forcing them to prioritize innovation and process optimization.

Key Focus Areas Shaping the Modern Industry

What are the most significant trends transforming industrial fabrication today? From shop floor robotics to global supply chain management, several key areas are redefining what it means to be a top-tier manufacturer.

Automation and Robotics: The Future of Precision?

In an industry known for its physically demanding and often hazardous work, automation and robotics have emerged as game-changers. But is the human touch becoming obsolete? On the contrary, advanced robotics are now tools that augment human skill, not replace it. Robotic welding cells can perform repetitive tasks with flawless repeatability, ensuring every weld is perfect and consistent. This not only dramatically increases production speed and efficiency but also significantly improves worker safety by moving them away from high-risk environments. This synergy between human expertise and robotic precision is the new standard, allowing manufacturers to tackle larger and more complex projects with confidence.

Material Science and Metallurgy: More Than Just Steel

More On 360mediahub ::

- Mango AI's AI Kissing Video Generator Transforms Photos into Realistic Kiss Videos

- Beijing Water Design: China Best Musical Fountain Manufacturer

- Unapologetic, Unstoppable, and Undeniably Leaving A Big Impact On The Rock Genre

- Alex Barkley, Recognized by BestAgents.us as a 2025 Top Agent

- Regenerix Gold® Helps Define the “Active Longevity” Movement in Daily Joint Nutrition

While steel remains a cornerstone of the fabrication industry, the materials landscape has never been more diverse. Modern projects require a wide range of materials, from high-strength low-alloy (HSLA) steels to specialized aluminum, titanium, and corrosion-resistant alloys. Each of these materials presents unique challenges and requires a specific approach to welding and fabrication. A forward-thinking manufacturer must have a deep understanding of metallurgy to ensure the structural integrity of the final product. Can a one-size-fits-all approach work when materials are so varied? The answer is a clear no. Expertise in material science is no longer a luxuryits a fundamental requirement.

Quality and Traceability: The Imperative of Certification

In industries like aerospace, energy, and oil & gas, the failure of a single component can have catastrophic consequences. As a result, quality and traceability have become non-negotiable. Modern manufacturers must adhere to stringent international standards (such as ISO 9001, AWS, and ASME) and provide comprehensive documentation for every step of the process. From the origin of the raw material to the final weld, every detail must be logged and verified. This level of transparency builds trust and ensures compliance. After all, can you truly trust a partner without transparent quality protocols and full traceability?

Integrated Services: The Rise of the 'One-Stop Shop'

Today's clients are looking to simplify their supply chains. The days of hiring separate vendors for cutting, welding, machining, and finishing are becoming a thing of the past. The trend is clearly toward a single, integrated partner who can manage the entire project from start to finish. This "one-stop shop" model streamlines communication, reduces administrative burden, and minimizes the risk of errors that can occur when a project changes hands. For both the client and the manufacturer, it's a win-win, leading to faster project completion and reduced overall costs.

Openex: A Deep Dive into Our One-Stop Process

Openex has not only observed these industry trendswe have built our entire business model around them. As a leader in One-Stop Industrial Welding And Fabrication, we understand that our value proposition is not just about a single service but about providing a comprehensive, end-to-end solution. Our process is a reflection of the industrys future, combining advanced technology, deep expertise, and a relentless focus on quality and service.

Our Core Advantage: The Power of Integration

What sets Openex apart in a competitive global market? It's our powerful synergy of technology, expertise, and seamless project management, all under one roof.

Advanced Technology Meets Human Expertise

Our commitment to innovation begins with our state-of-the-art facility. We are equipped with cutting-edge machinery, including high-power laser and plasma cutters, precision CNC press brakes, and advanced robotic welding cells. But we know that technology alone is never enough. This world-class equipment is operated and managed by a team of highly skilled engineers and experienced welders who bring years of practical knowledge to every project. This blend of technical prowess and human expertise allows us to tackle even the most complex and demanding fabrication challenges with confidence and precision.

Seamless Project Management from Prototype to Production

One of Openexs greatest strengths is our ability to manage a project from its initial concept to final delivery. Our clients can bring us a design, and we handle the rest. This includes everything from material sourcing and prototyping to precision cutting, welding, machining, and final finishing. We take the stress and complexity out of the project, allowing our clients to focus on their core business. Our meticulous quality control process ensures that every component is built to exacting specifications, giving our clients the peace of mind that comes from a single, accountable partner.

Applications in Action: Products and Their Purpose

Our expertise in industrial welding and fabrication is demonstrated through the diverse range of high-quality components we produce for various industries. Each product is a testament to our engineering prowess and our ability to tailor solutions to specific, demanding applications.

Mining & Engineering: For an industry where durability and safety are non-negotiable, we manufacture robust control cabins, heavy-duty chassis and frames for machinery, and specialized steel structures for large-scale mining and excavation equipment.

Oil & Gas: In a sector that demands reliability under extreme pressure, we provide high-pressure pipe spools, structural platforms, and protective enclosures for sensitive equipment. Our products are built to withstand corrosive environments and demanding operational conditions.

Automotive & Aerospace: We produce a wide range of components, from custom chassis and sub-frames for heavy-duty vehicles to specialized engine mounts and critical structural coponents for both airframes and ground support equipment, all with the precision required by these exacting industries.

Energy: Our products are integral to the global energy sector, from traditional power generation to renewable sources. We fabricate wind turbine tower sections, foundational supports for solar power plants, and large components for power generation facilities, all designed for long-term durability.

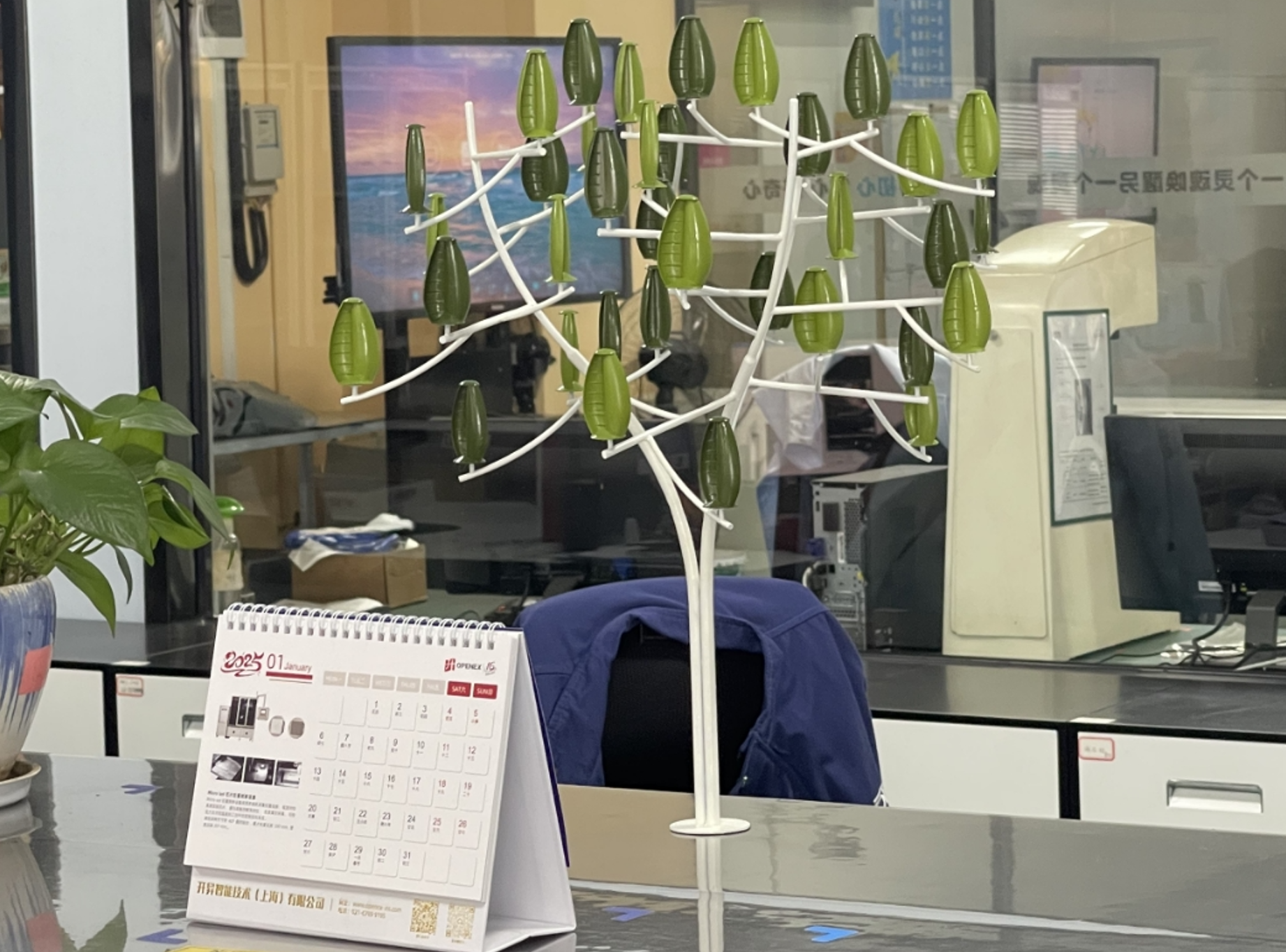

Here below is one of unique wind tree that we produce at customers specification, from metal fabricated tree and the plastic injected leaves on it working as wind turbines to produce continuate power even with breeze (speed under 2.5m/s)

(The actual wind tree can be 5 meters tall)

Construction: We provide the backbone for modern infrastructure. Our work includes prefabricated steel trusses, custom structural beams for high-rises, and industrial-grade welded components for bridges and other major projects, all built to the highest standards of safety and strength.

Openex is more than just a manufacturer; we are a strategic partner for businesses that can last decades. We have built our reputation on a foundation of trust, quality, and a commitment to providing Reliable Industrial Welding And Fabrication Services that meet the complex needs of our global clientele. When your project demands the best in quality, experience, and efficiency, isnt it time you trusted a one-stop solution?

To learn more about our capabilities and how we can elevate your next project, visit our website: https://www.cncmetalworking.com/

Media Contact

Openex

+86 186 5928 0806

Our Offices:No. 99 Yilan Rd., Xiamen , CN.

Source :Openex

This article was originally published by IssueWire. Read the original article here.

5 day's ago