Xian, Shanxi Jan 3, 2026 (Issuewire.com) - Building for longevity in harsh environments requires more than just high-grade panels; it demands an evolution in how those panels are secured. Consider a coastal solar farm or a massive industrial warehouse situated near a high-humidity port. In these settings, the metal roof is the first line of defense against the elements. However, the integrity of that entire structure often rests on a component no larger than a human thumb. When traditional fasteners fail due to salt spray or high wind loads, the results are catastrophicleaks, structural instability, and costly downtime.

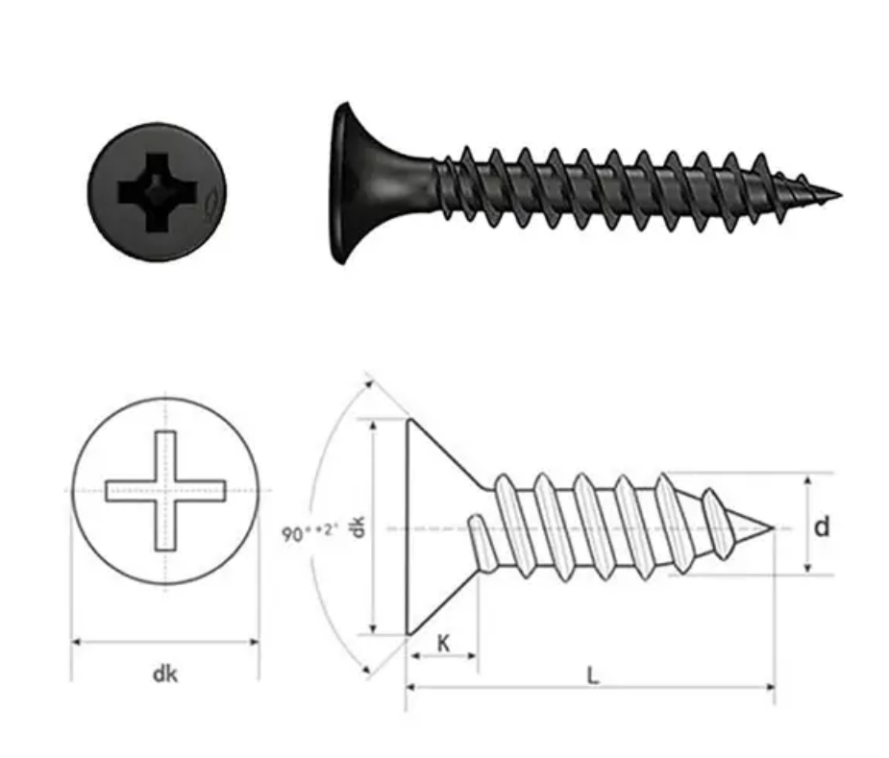

As global infrastructure demands more resilient solutions, the role of a High Quality Metal Roofing Screws Producer In China has shifted from simple manufacturing to advanced metallurgical engineering. Metal roofing screws are specialized fasteners designed with integrated sealing washers and specific thread geometries to pierce metal sheets while maintaining a watertight seal. They are the essential connective tissue in modern pre-engineered metal buildings, agricultural sheds, and renewable energy installations.

The Global Shift Toward High-Performance Fastening Infrastructure

The global construction landscape is currently undergoing a significant transformation. With the rise of sustainable building practices and the increasing frequency of extreme weather events, the industry is moving away from "good enough" materials toward high-performance components. This shift is particularly evident in the fastening sector, where the demand for bimetal and anti-corrosive solutions is skyrocketing. Modern projects no longer view fasteners as a commodity but as a critical engineering requirement that dictates the lifespan of the entire building envelope.

China has emerged as a pivotal player in this evolution. While the region was once viewed primarily as a source for high-volume, low-cost hardware, it has matured into a hub for sophisticated precision engineering. Chinese producers are now leading the way in integrating advanced coatings and material science into standard production lines, meeting the stringent ISO and international quality standards required for Tier-1 infrastructure projects. This development is driven by a massive domestic investment in high-tech manufacturing and a robust supply chain that allows for rapid innovation in fastener design. Today, a metal roofing screws producer in China is often at the forefront of metallurgical research, developing products that can withstand decades of exposure in diverse climates.

Technical Excellence in Modern Fastener Manufacturing

Within this competitive industrial climate, Fasto Industrial Co., Ltd. (Fasto) has established itself as a specialist in high-performance fastening technology. Based in China, the company focuses on addressing the most persistent challenges in the industry: drilling efficiency and long-term corrosion resistance. Their development of bimetal self-drilling screws represents a significant leap forward in metal roofing screws technology. By fusing a hardened carbon steel drill point with a stainless steel body, these fasteners provide the strength to pierce thick metal plates combined with the chemical stability to resist rust in acidic or salty environments.

l Advanced Metallurgy and Quality Control

More On 360mediahub ::

- Daniel Fridman, Recognized by BestAgents.us as a 2026 Top Agent

- China Top Frozen Food Pouches Gain FDA Certification From Yinshili Packaging

- International dancer Roberta Di Laura among top 100 Italian Excellences

- The First Decentralized OTC Platform

- ReAction Unaffected by 2026 Hemp Law; Patented Tech and Vertical Integration Position Company as Industry Leader

The technical distinction of these modern screws lies in their specialized coatings and structural integrity. Unlike standard hardware, these fasteners undergo rigorous treatments such as mechanical galvanizing, Ruspert coating, or dacromet finishing. These layers are not merely aesthetic; they are engineered to prevent galvanic corrosion, which occurs when dissimilar metals react in a moist environment. By refining the interface structure, manufacturers have been able to minimize hydrogen embrittlement, a common cause of sudden fastener failure in high-load applications.

Comprehensive Hardware Capability

Beyond specialized bimetal solutions, the core advantage of a modern manufacturer lies in its breadth of capability. A reliable single source for complete fastening solutions must offer a wide range of precision hardware, including rivets, bolts, nuts, washers, and thread rods. By utilizing materials ranging from stainless steel and titanium to copper, a producer can serve diverse sectors from coastal roofing to solar PV systems and aluminum façades. This comprehensive approach ensures that every component of an assembly meets the same high quality standards, reducing the risk of component mismatch during installation.

Comparing Modern Metal Roofing Screws with Traditional Methods

When evaluating the transition from traditional fastening methods to modern high-performance solutions, the advantages become clear across several key metrics including labor efficiency, material longevity, and structural safety.

The Limitations of Traditional Fastening

Historically, metal roofs were often secured using standard carbon steel screws or even older labor-intensive methods like hook bolts and manual pre-drilling. These traditional approaches present several systemic risks:

- Pre-drilling requirements: Older methods often require a pilot hole to be drilled before the fastener is inserted. This doubles the labor time and increases the margin for error, as misaligned holes can lead to leaks.

- Corrosion vulnerability: Standard steel fasteners without advanced coatings begin to oxidize almost immediately when exposed to moisture. Once the head of a screw rusts, the seal is broken, leading to water ingress and the eventual degradation of the underlying structure.

- Structural fatigue: Traditional screws often lack the flexibility to handle the thermal expansion and contraction of metal roof panels. Over time, this stress can cause the fastener to back out or snap.

The Superiority of Modern Self-Drilling Solutions

In contrast, high-performance metal roofing screws offer a streamlined and more durable alternative. By integrating the drilling, tapping, and fastening into a single motion, these screws revolutionize the installation process.

- Enhanced installation speed: Self-drilling points eliminate the need for separate drill bits. This significantly reduces onsite labor costs and allows for faster project completion.

- Superior sealing: Modern screws are equipped with EPDM washers that are UV-resistant. When the screw is driven, the washer compresses to form a permanent, weather-tight gasket around the entry point.

- Advanced metallurgical bonding: For projects in coastal or industrial areas, bimetal screws provide a level of protection that traditional galvanized screws cannot match. The stainless steel shank ensures that the fastener will not rust through, even if the outer coating is scratched.

- High load capacity: Precision-engineered thread profiles provide higher pull-out resistance, ensuring that roofing panels remain secure during high-wind events or under heavy snow loads.

Strategic Applications in Energy and Construction

The application of these advanced fastening solutions extends far beyond simple residential roofing. In the renewable energy sector, solar PV systems rely on metal roofing screws to secure mounting rails to metal substrates. In these scenarios, the fasteners must withstand decades of outdoor exposure while supporting the weight and wind-uplift of the panels. Similarly, in the construction of aluminum façades, the precision of the fastener is paramount to both the aesthetic and structural success of the building envelope.

By acting as a reliable single source for complete fastening solutions, a sophisticated roducer ensures that every component of the assembly works in harmony. As the industry continues to prioritize life-cycle costs over initial material expenses, the shift toward high-quality fasteners is accelerating. Choosing a specialized producer ensures that the fastening pointsthe smallest components of a projectbecome its most reliable assets.

For more information on high-performance fastening solutions and bimetal technology, visit Fasto Industrial Co., Ltd. at https://www.fastoscrews.com/.

Media Contact

Fasto Industrial Co., Ltd.

+86-029-81165337

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi'an, China

Source :Fasto Industrial Co., Ltd.

This article was originally published by IssueWire. Read the original article here.

2 day's ago